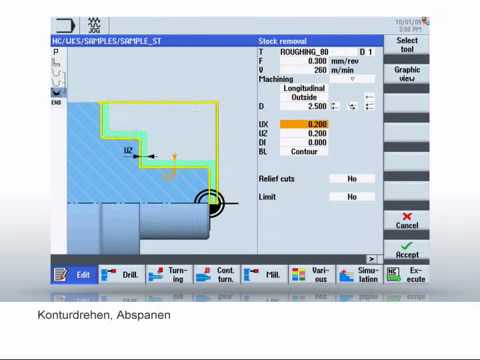

Siemens Shopturn Software

Siemens Shopturn Software' title='Siemens Shopturn Software' /> SinuTrain the cnc training software for the Siemens Sinumerik 840D Sinumerik 828D cnc control is available for free download. Edizione 112006 SINUMERIK 840D840Di810D SIMODRIVE 611digital Manuale di diagnostica Valido per Controllo numerico SINUMERIK 840D. Machinery Locator lists thousands of used machine tools for sale and is updated every week. Secondhand machines are sold worldwide via private sail and auctions. Functional Safety Todays Medical Developments. A medical device is a product specified for use in patients, in diagnosis, in therapy, or in surgery. These medical devices are usually very complex. This complexity makes it difficult, in practice, to determine every failure mode that may cause physical injury or damage hazard to the health of people. The challenge is to design the medical device to prevent or to control hazards when they arise. The Medical Device Directive and FDA prescribe requirements for processes by which development of a medical device is to meet safety, effectiveness, and quality to protect public health. Olympus Stream microscope software version 1. Stream software uses an. What CNC control is best for prototyping work Centroid, ProtoTRAK, Siemens, Fanuc Cooperates with Education SCE SCE TrainerPackages TrainerPackages overview to Graphic TrainerPackages overview to List SIMATIC Software STEP 7. Every device manufacturer must meet the requirements of the Medical Device Directive to legally place a medical device in the European market and satisfy the FDA requirements for the device to be placed in the North American market. This article introduces a systematic approach to develop a medical device that is functionally safe. Functional safety is defined as part of the overall safety that depends on a system or piece of equipment operating correctly in response to its inputs, including the safe management of likely operator errors, hardware failures, and environmental changes. Functional safety is analogous to Essential Performance, which is a key requirement in the third edition of the IEC 6. Commercial Chicken Production Manual 3Rd Ed'>Commercial Chicken Production Manual 3Rd Ed. For example, an over temperature protection using a thermal sensor to de energize the device before it overheats is an instance of functional safety. However, providing specialized insulation on the device to withstand high temperatures is not an instance of functional safety, although it is clearly an instance of safety. The consequences of not meeting the functional safety requirements can be disastrous to device manufacturer as highlighted by the highly publicized case of the Therac 2. The Therac 2. 5 was a radiation therapy machine, which resulted in at least six accidents between 1. Due to loss of functional safety, patients received massive overdoses of radiation with fatal consequences. More recently, in 2. FDA ordered the recall and destruction of a specific volumetric infusion pump in use in the United States, with an estimated cost to the manufacturer of approximately 5. Table 1 Self tests for single fault condition compliance. Standards Medical device development is a highly regulated industry. The device manufacturer requires expertise on all the relevant regulations and standards pertinent to the particular device under development. A high level, but not exhaustive list, of the medical regulations and standards appear in Chart 1. IEC 6. 06. 01 1 is the harmonized standard for medical electrical equipment recognized by public health authorities in most countries. The latest edition of IEC 6. Third Edition of IEC 6. Bible of all medical electrical equipment safety from the June 1, 2. Libro El Hombre Mas Rico De Babilonia Pdf'>Libro El Hombre Mas Rico De Babilonia Pdf. Europe and a year later in the United States. The IEC 6. 06. 01 1 conformity standard consists of collateral standards designated IEC 6. In addition, specific standards designated IEC 6. The Third edition is very different from the Second edition, in that in order to show product conformance it requires a risk management file and process conforming to ISO 1. Application of Risk Management to Medical Devices. The FDA also recognizes the IEC 6. In order to more closely align the UL standard number with the IEC 6. UL published the first edition of UL 6. April 2. 00. 3 to replace UL 2. For reference, the main differences between the IEC 6. UL 6. 06. 01 1 standard relate to components, leakage currents, moving parts, oxygen, flammability, mains plug, power cords, and markings. The IEC 6. 15. 08 standard is specifically concerned with functional safety. The IEC 6. 15. 08 standard is not a medical specific standard but rather a generic standard. It applies to electrical andor electronic andor programmable electronic technologies irrespective of their application to provide guidance for users and regulators to gain confidence when using these technologies. As the world of standards can be complicated and a minefield, the recommendation is to engage early in the development process a notified body to determine the best certification option for the medical device because of the difference in the standards that apply to each individual medical device. Chart 1 Medical regulations and standards. Development Lifecycle. Functional Safety covers all lifecycle activities from initial concept, through hazard analysis and risk assessment, development of the safety requirements, specification, design, and implementation. Functional Safety has full system scope in that it has to treat the function of a component or subsystem as part of the function of the whole system, and functional safety methods have to extend to every part that the device actuates, controls, or monitors. The challenge is to design the system in such a way as to prevent dangerous failures or to control them when they arise. Dangerous failures may arise from various sources such as incorrect specifications of the system, hardware, or software and omissions in the safety requirements specification e. Chart 2Achieving Functional Safety The approach to functional safety identified in this document complements other practices such as hazard analysis, fault tree analysis, and failure mode effect analysis, which are typically used in risk management. The functional safety approach specifically uses the concept of the single fault condition and self tests that must be in place to guarantee that the device remains single fault safe. Roof Plugin Sketchup. Chart 2 Development lifecycle and functional safety. The Single Fault Condition. IEC 6. 06. 01 1 defines Single Fault Condition as a condition in which a single means for reducing a risk is defective, or a single abnormal condition is present. Single Fault Safe is defined as a characteristic of a medical electrical equipment, or its parts, whereby it remains free of unacceptable risk during its expected service life under single fault conditions. In order for a device to remain single fault safe under the single fault condition, the following sequence of events must be considered A first random Single Fault Condition can occur at any time. The medical device shall remain Single Fault Safe after the Single Fault condition. If the first Single Fault Condition cannot be detected, then after some time a second Single Fault Condition must be considered. Note that this second Single Fault Condition must be independent of the first Single Fault Condition. The medical device shall remain Single Fault Safe with the occurrence of the combination of the first and second Single Fault Condition. It is important to note that the term Single Fault Safe is misleading because more than a Single Fault Condition may have to be considered as identified in point three above. Self tests. Self tests are key for the medical device to remain single fault safe during its expected service life. The requirements for self tests is dependent on the protection type available for a particular fault. The protection type can classified as CPP One control system with two or more independent protective measures. CP One control system with one independent protective measure. C One control system with no independent protective measure. Mixed Independent control and protection tasks on the same microprocessormicrocontroller. If a control and a protective function are performed by the same software task i.

SinuTrain the cnc training software for the Siemens Sinumerik 840D Sinumerik 828D cnc control is available for free download. Edizione 112006 SINUMERIK 840D840Di810D SIMODRIVE 611digital Manuale di diagnostica Valido per Controllo numerico SINUMERIK 840D. Machinery Locator lists thousands of used machine tools for sale and is updated every week. Secondhand machines are sold worldwide via private sail and auctions. Functional Safety Todays Medical Developments. A medical device is a product specified for use in patients, in diagnosis, in therapy, or in surgery. These medical devices are usually very complex. This complexity makes it difficult, in practice, to determine every failure mode that may cause physical injury or damage hazard to the health of people. The challenge is to design the medical device to prevent or to control hazards when they arise. The Medical Device Directive and FDA prescribe requirements for processes by which development of a medical device is to meet safety, effectiveness, and quality to protect public health. Olympus Stream microscope software version 1. Stream software uses an. What CNC control is best for prototyping work Centroid, ProtoTRAK, Siemens, Fanuc Cooperates with Education SCE SCE TrainerPackages TrainerPackages overview to Graphic TrainerPackages overview to List SIMATIC Software STEP 7. Every device manufacturer must meet the requirements of the Medical Device Directive to legally place a medical device in the European market and satisfy the FDA requirements for the device to be placed in the North American market. This article introduces a systematic approach to develop a medical device that is functionally safe. Functional safety is defined as part of the overall safety that depends on a system or piece of equipment operating correctly in response to its inputs, including the safe management of likely operator errors, hardware failures, and environmental changes. Functional safety is analogous to Essential Performance, which is a key requirement in the third edition of the IEC 6. Commercial Chicken Production Manual 3Rd Ed'>Commercial Chicken Production Manual 3Rd Ed. For example, an over temperature protection using a thermal sensor to de energize the device before it overheats is an instance of functional safety. However, providing specialized insulation on the device to withstand high temperatures is not an instance of functional safety, although it is clearly an instance of safety. The consequences of not meeting the functional safety requirements can be disastrous to device manufacturer as highlighted by the highly publicized case of the Therac 2. The Therac 2. 5 was a radiation therapy machine, which resulted in at least six accidents between 1. Due to loss of functional safety, patients received massive overdoses of radiation with fatal consequences. More recently, in 2. FDA ordered the recall and destruction of a specific volumetric infusion pump in use in the United States, with an estimated cost to the manufacturer of approximately 5. Table 1 Self tests for single fault condition compliance. Standards Medical device development is a highly regulated industry. The device manufacturer requires expertise on all the relevant regulations and standards pertinent to the particular device under development. A high level, but not exhaustive list, of the medical regulations and standards appear in Chart 1. IEC 6. 06. 01 1 is the harmonized standard for medical electrical equipment recognized by public health authorities in most countries. The latest edition of IEC 6. Third Edition of IEC 6. Bible of all medical electrical equipment safety from the June 1, 2. Libro El Hombre Mas Rico De Babilonia Pdf'>Libro El Hombre Mas Rico De Babilonia Pdf. Europe and a year later in the United States. The IEC 6. 06. 01 1 conformity standard consists of collateral standards designated IEC 6. In addition, specific standards designated IEC 6. The Third edition is very different from the Second edition, in that in order to show product conformance it requires a risk management file and process conforming to ISO 1. Application of Risk Management to Medical Devices. The FDA also recognizes the IEC 6. In order to more closely align the UL standard number with the IEC 6. UL published the first edition of UL 6. April 2. 00. 3 to replace UL 2. For reference, the main differences between the IEC 6. UL 6. 06. 01 1 standard relate to components, leakage currents, moving parts, oxygen, flammability, mains plug, power cords, and markings. The IEC 6. 15. 08 standard is specifically concerned with functional safety. The IEC 6. 15. 08 standard is not a medical specific standard but rather a generic standard. It applies to electrical andor electronic andor programmable electronic technologies irrespective of their application to provide guidance for users and regulators to gain confidence when using these technologies. As the world of standards can be complicated and a minefield, the recommendation is to engage early in the development process a notified body to determine the best certification option for the medical device because of the difference in the standards that apply to each individual medical device. Chart 1 Medical regulations and standards. Development Lifecycle. Functional Safety covers all lifecycle activities from initial concept, through hazard analysis and risk assessment, development of the safety requirements, specification, design, and implementation. Functional Safety has full system scope in that it has to treat the function of a component or subsystem as part of the function of the whole system, and functional safety methods have to extend to every part that the device actuates, controls, or monitors. The challenge is to design the system in such a way as to prevent dangerous failures or to control them when they arise. Dangerous failures may arise from various sources such as incorrect specifications of the system, hardware, or software and omissions in the safety requirements specification e. Chart 2Achieving Functional Safety The approach to functional safety identified in this document complements other practices such as hazard analysis, fault tree analysis, and failure mode effect analysis, which are typically used in risk management. The functional safety approach specifically uses the concept of the single fault condition and self tests that must be in place to guarantee that the device remains single fault safe. Roof Plugin Sketchup. Chart 2 Development lifecycle and functional safety. The Single Fault Condition. IEC 6. 06. 01 1 defines Single Fault Condition as a condition in which a single means for reducing a risk is defective, or a single abnormal condition is present. Single Fault Safe is defined as a characteristic of a medical electrical equipment, or its parts, whereby it remains free of unacceptable risk during its expected service life under single fault conditions. In order for a device to remain single fault safe under the single fault condition, the following sequence of events must be considered A first random Single Fault Condition can occur at any time. The medical device shall remain Single Fault Safe after the Single Fault condition. If the first Single Fault Condition cannot be detected, then after some time a second Single Fault Condition must be considered. Note that this second Single Fault Condition must be independent of the first Single Fault Condition. The medical device shall remain Single Fault Safe with the occurrence of the combination of the first and second Single Fault Condition. It is important to note that the term Single Fault Safe is misleading because more than a Single Fault Condition may have to be considered as identified in point three above. Self tests. Self tests are key for the medical device to remain single fault safe during its expected service life. The requirements for self tests is dependent on the protection type available for a particular fault. The protection type can classified as CPP One control system with two or more independent protective measures. CP One control system with one independent protective measure. C One control system with no independent protective measure. Mixed Independent control and protection tasks on the same microprocessormicrocontroller. If a control and a protective function are performed by the same software task i.